About AZO plant engineering

The AZO Group is one of the most experienced companies worldwide when it comes to automatic raw material handling.

From engineering and the supply of individual components to the construction of complete turnkey plants, automation, assembly and comprehensive after-sales service, AZO, with over 70 years of experience in plant engineering, is an authority in automation solutions with a long-term perspective.

Services:

Project Support through Selmo Services

Industry:

Plant engineering - automatic raw material handling

Location:

Osterburken, Germany

Project overview

Project scope

- 91 PLC in- and outputs

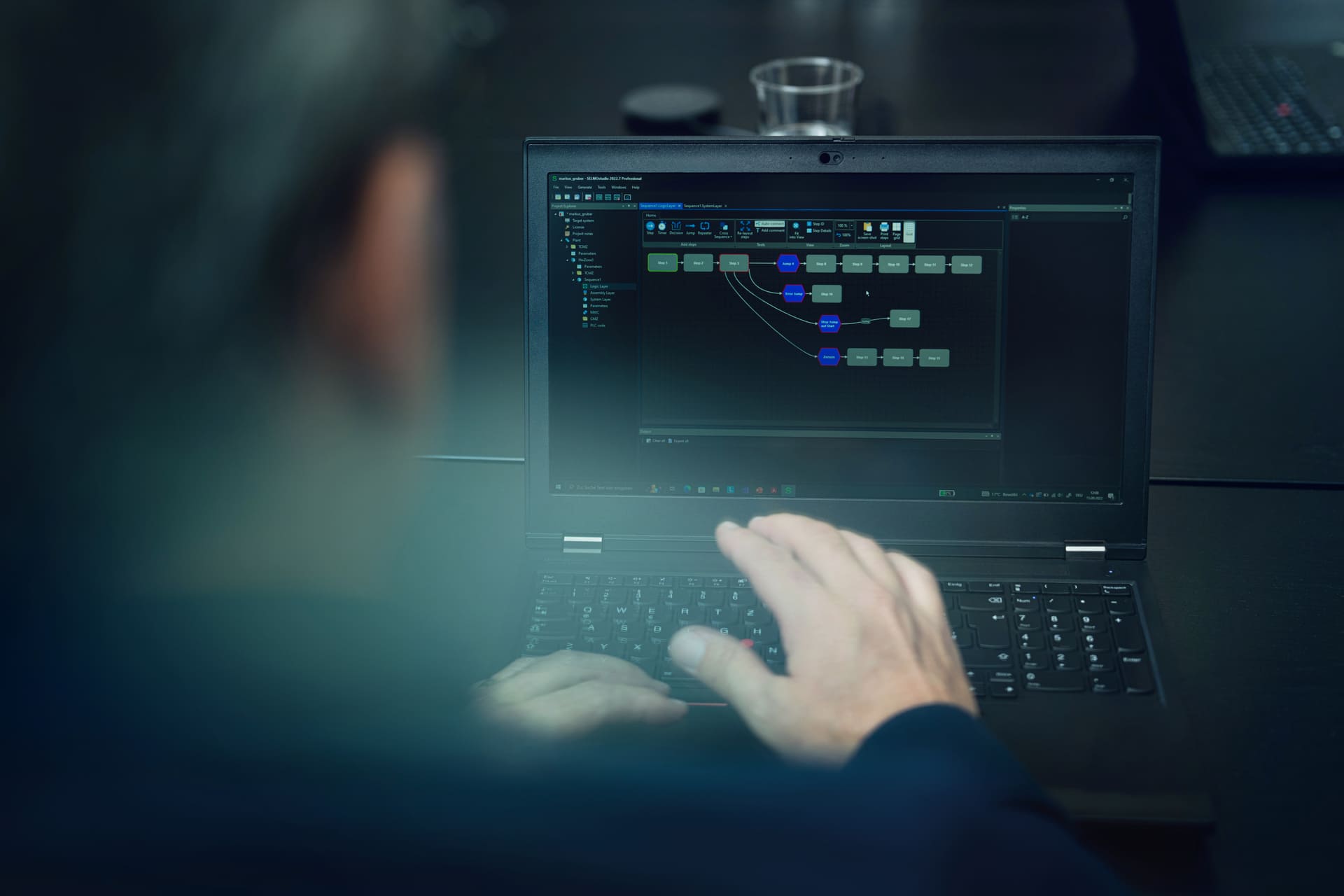

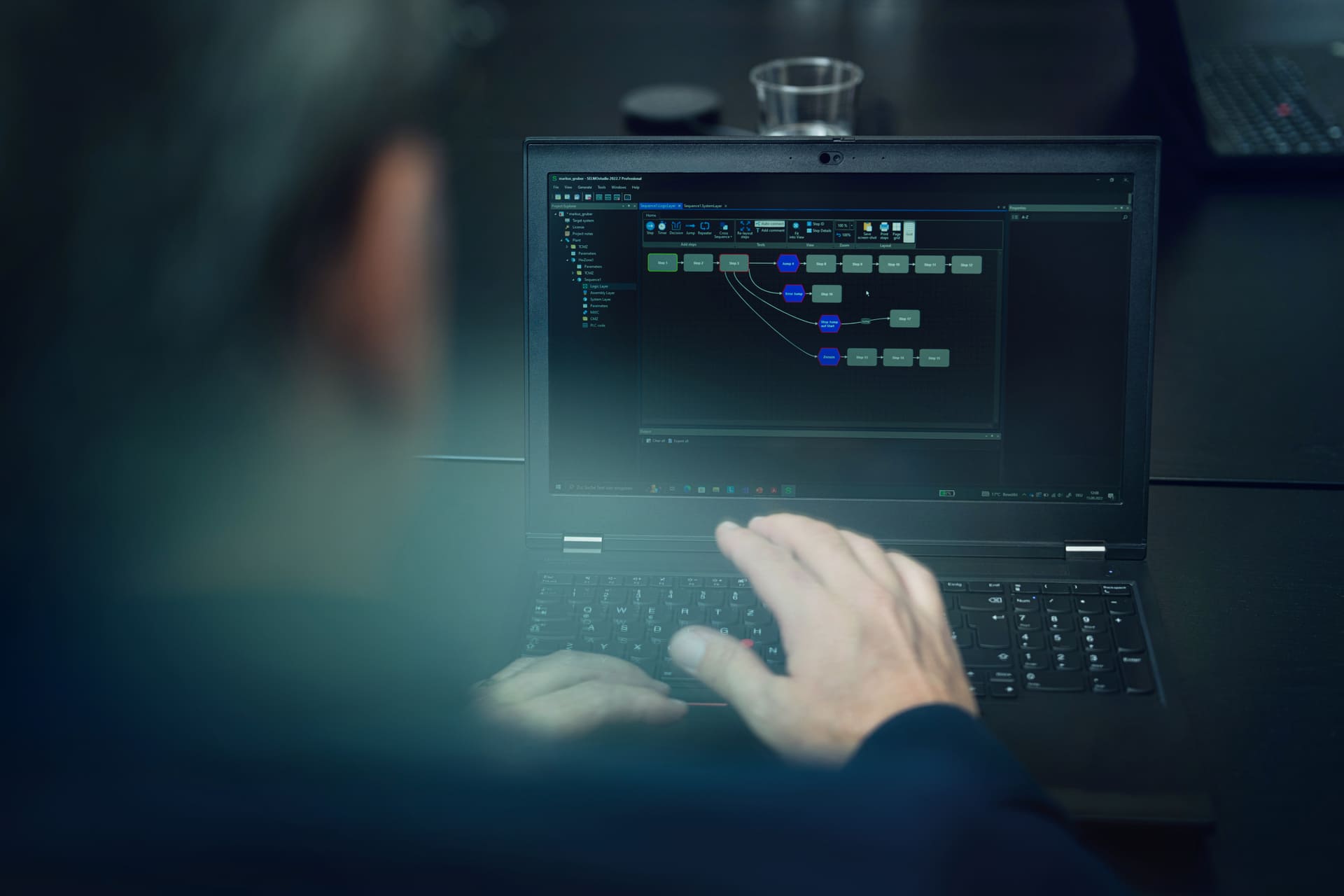

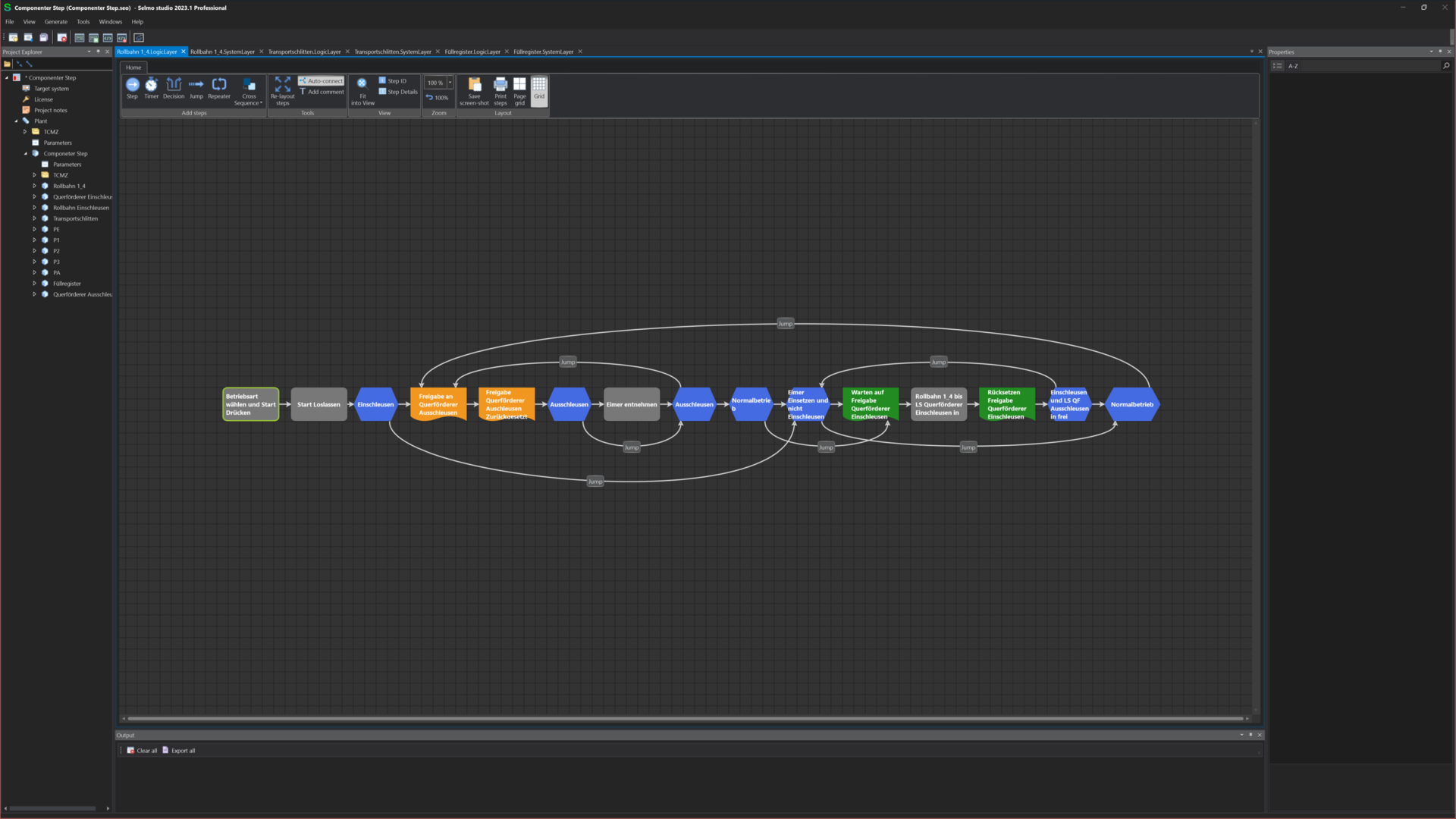

- 11 sequences with 134 steps modelled in the Selmo Studio

- 213 zones defined

- 15 constantly monitored zones

- 3 drivers

- 7330 lines of code

- 80 hours

Project timeline

- Preparation of the project in Selmo Studio based on the specifications

- Review of the modeling in the workshop on site at AZO

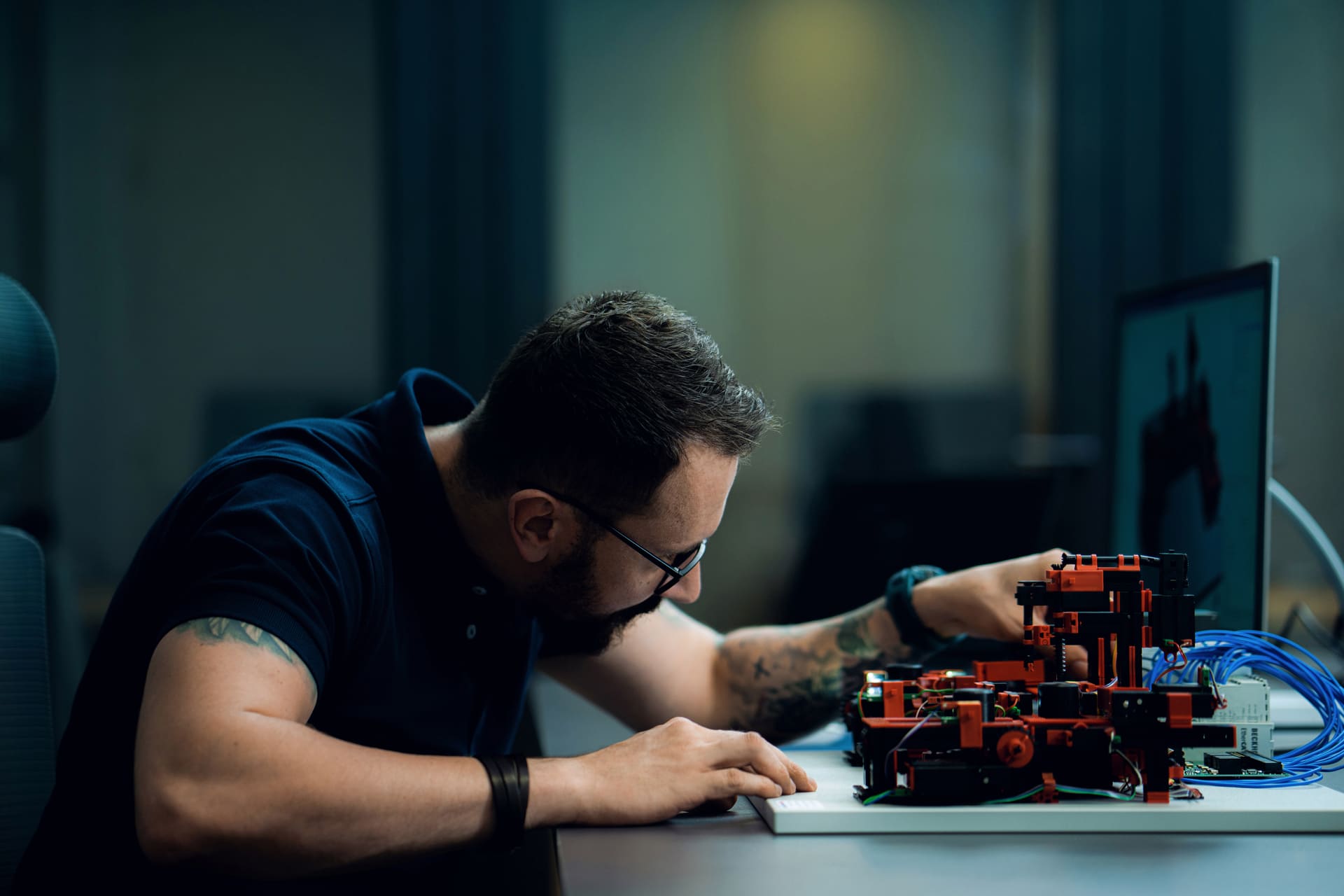

- I/O mapping and IBN of the real plant

- Kinematization of the provided step file of the plant

- Adaptation of the process by VIBN with the digital twin

Initial situation

AZO commissioned a retrofit of an existing plant to further understand the possibilities for plant modernization with the Selmo Solution. The existing process of the plant was modeled in Selmo Studio and adapted to the specifications. The company provided specific requirements for the functioning of the existing machine and the process. Based on this information, the Selmo team created a detailed model in Selmo Studio and presented the project in a workshop directly at AZO.

Then, a kinematization was carried out using the 3-D model and virtually put into operation to identify possible optimizations. Adjustments to the process could then be implemented quickly and effectively.

Implementation & result

Through virtual commissioning on a digital twin, possible improvements in the modeling became immediately visible. In addition, the easy handling of the process description and the resulting automatic generation of a complete and verifiable PLC program turned out to be a clear benefit.

As a result, nothing more stood in the way of the successful commissioning of the modernized plant.