About MAHLE Filtersysteme Austria GmbH

MAHLE is a leading international development partner and supplier to the automotive industry as well as a pioneer and technology driver for the mobility of the future.

Based on a broad systems competence consisting of Engine Systems and Components, Filtration, and Thermal Management, the group’s product portfolio addresses all the crucial issues relating to the powertrain and air conditioning technology. Thanks to its expertise in electric and electronic components and systems, MAHLE can thus also offer integrated system solutions for e-mobility.

Services:

Retrofit

Selmo Services

Industry:

Automotiv Industry

Location:

St. Michael ob Bleiburg, Austria

Project overview

Project goals

- The process of the machine becomes visible

- Control and monitoring are ensured

- Improvement of cycle times

Project timeline

- Analysis of the process flow.

- Analysis of status quo.

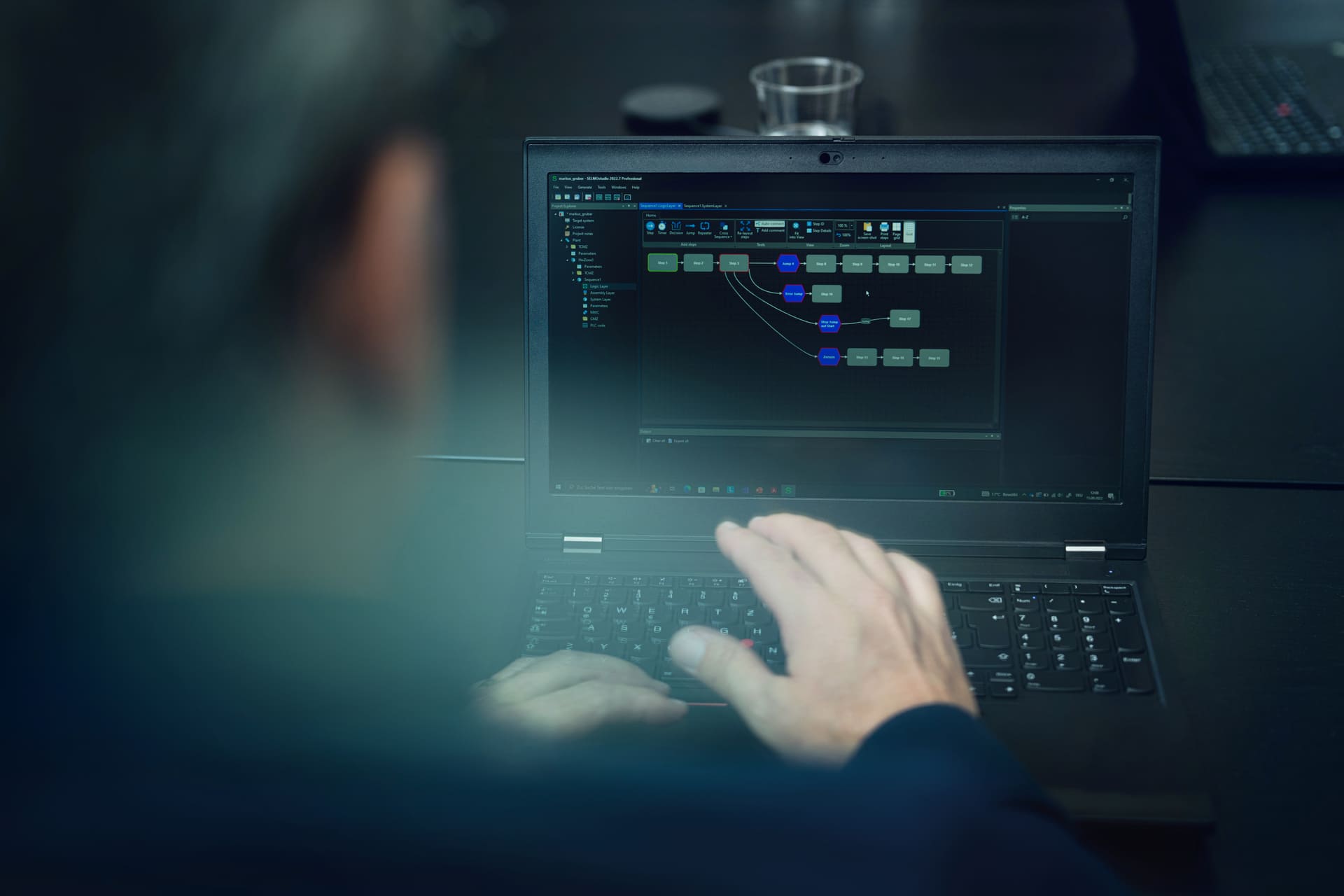

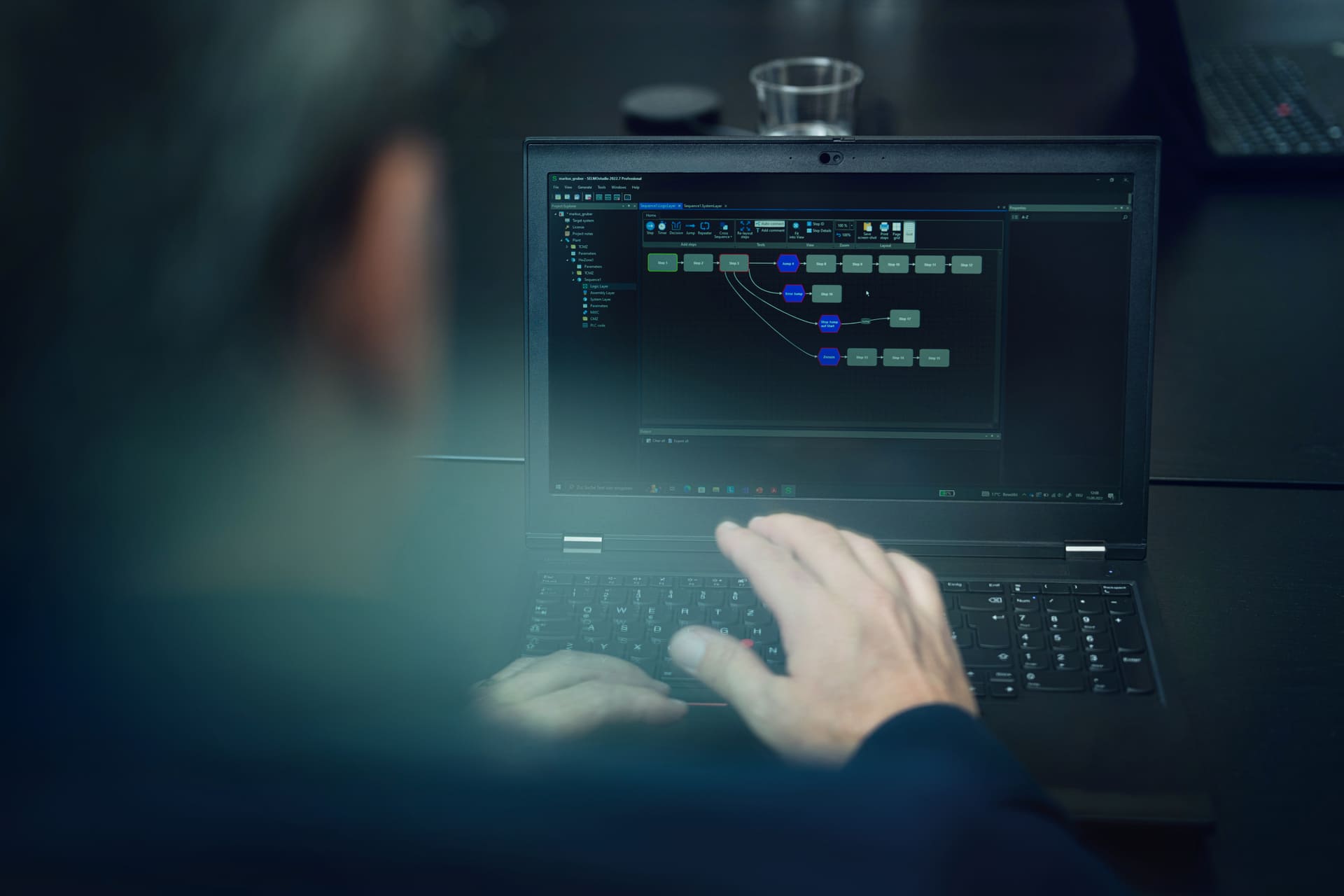

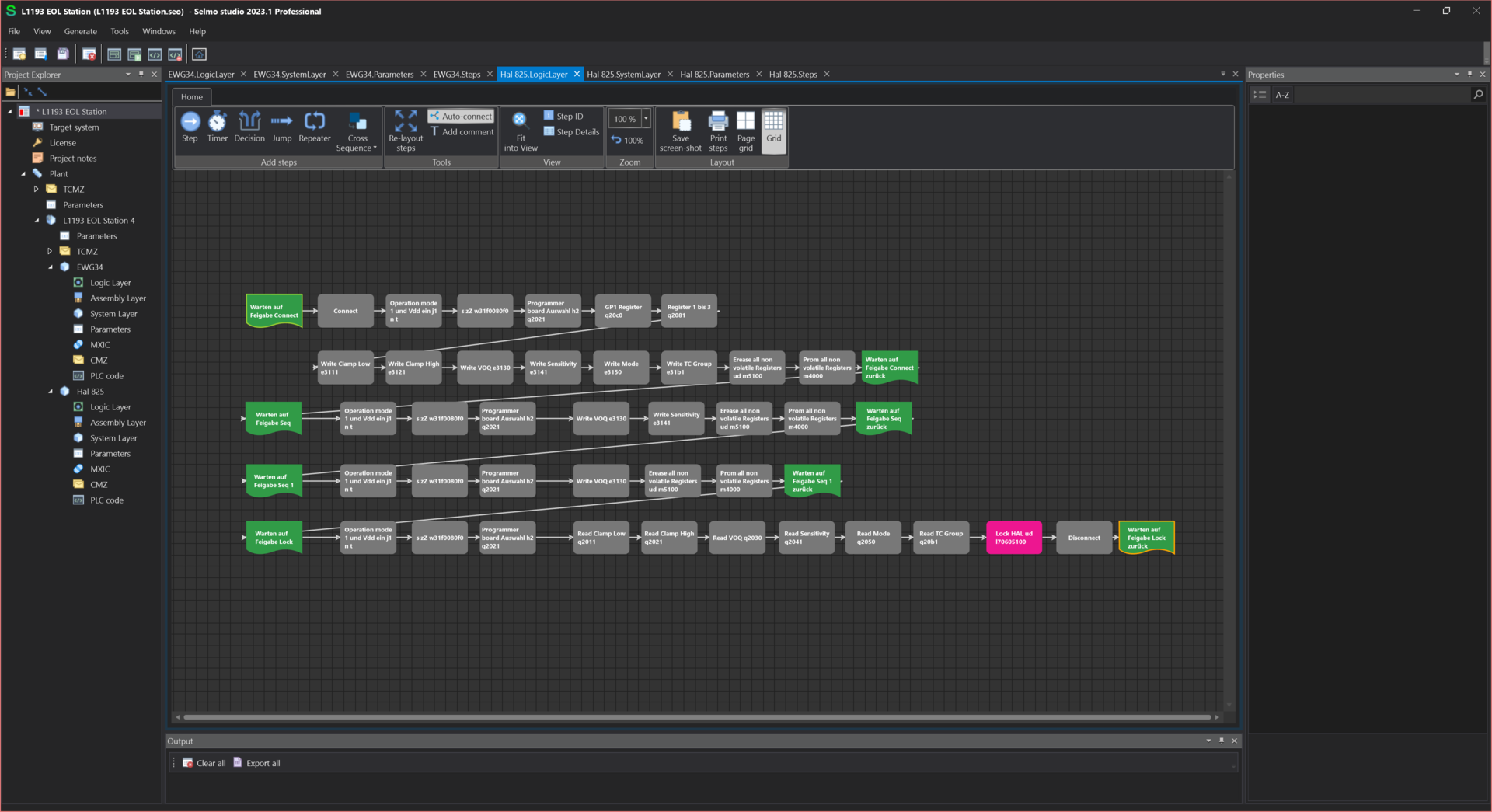

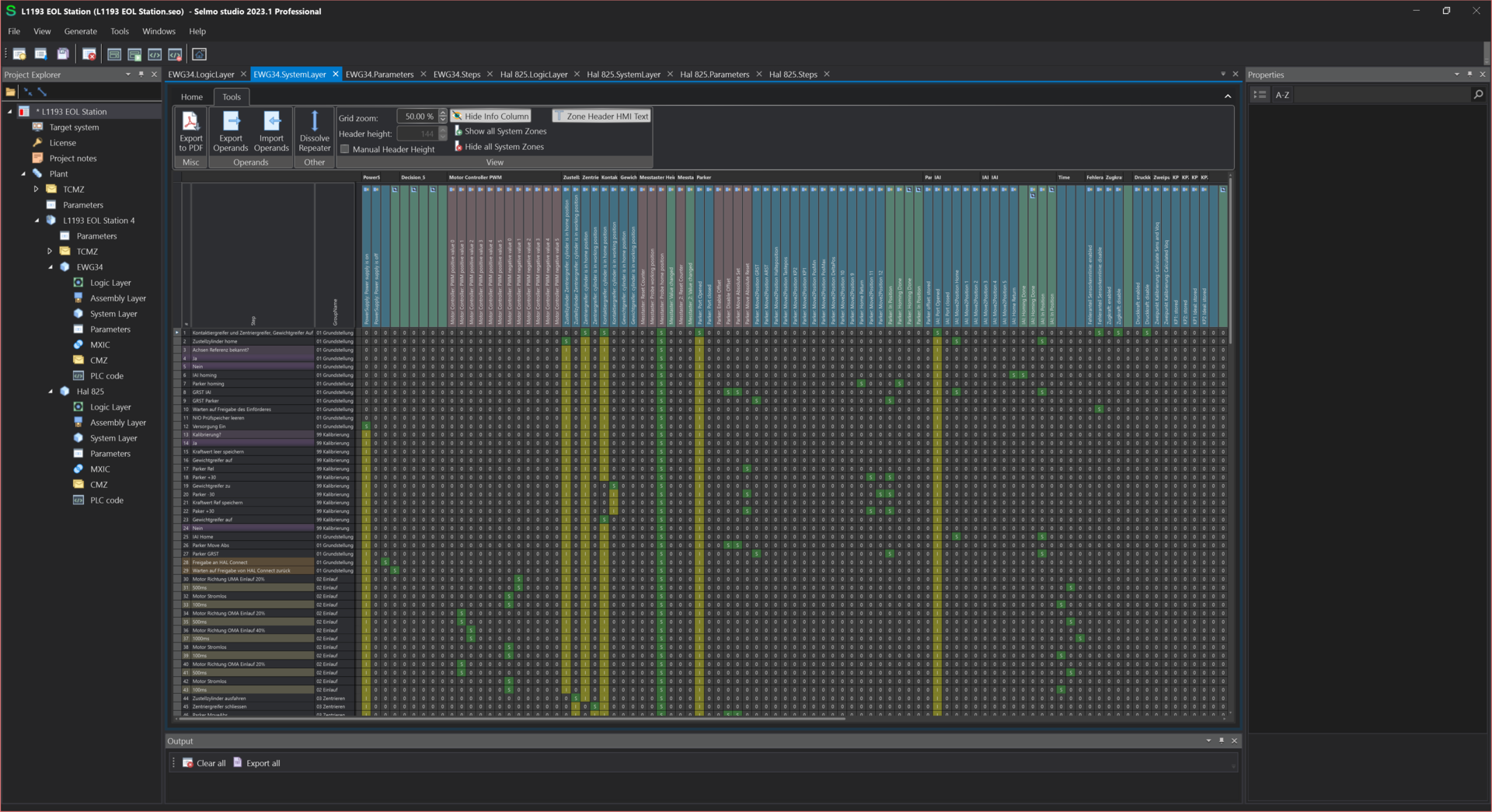

- Modeling of the process flow in Selmo Studio.

- Creation of the drivers according to the requirements of the machine.

- Implementation of the revised process model in the control system.

-

Commissioning and optimization of the machine.

-

HMI is used to control and diagnose the station.

-

Test data acquisition and storage in the MAHLE network.

Initial situation

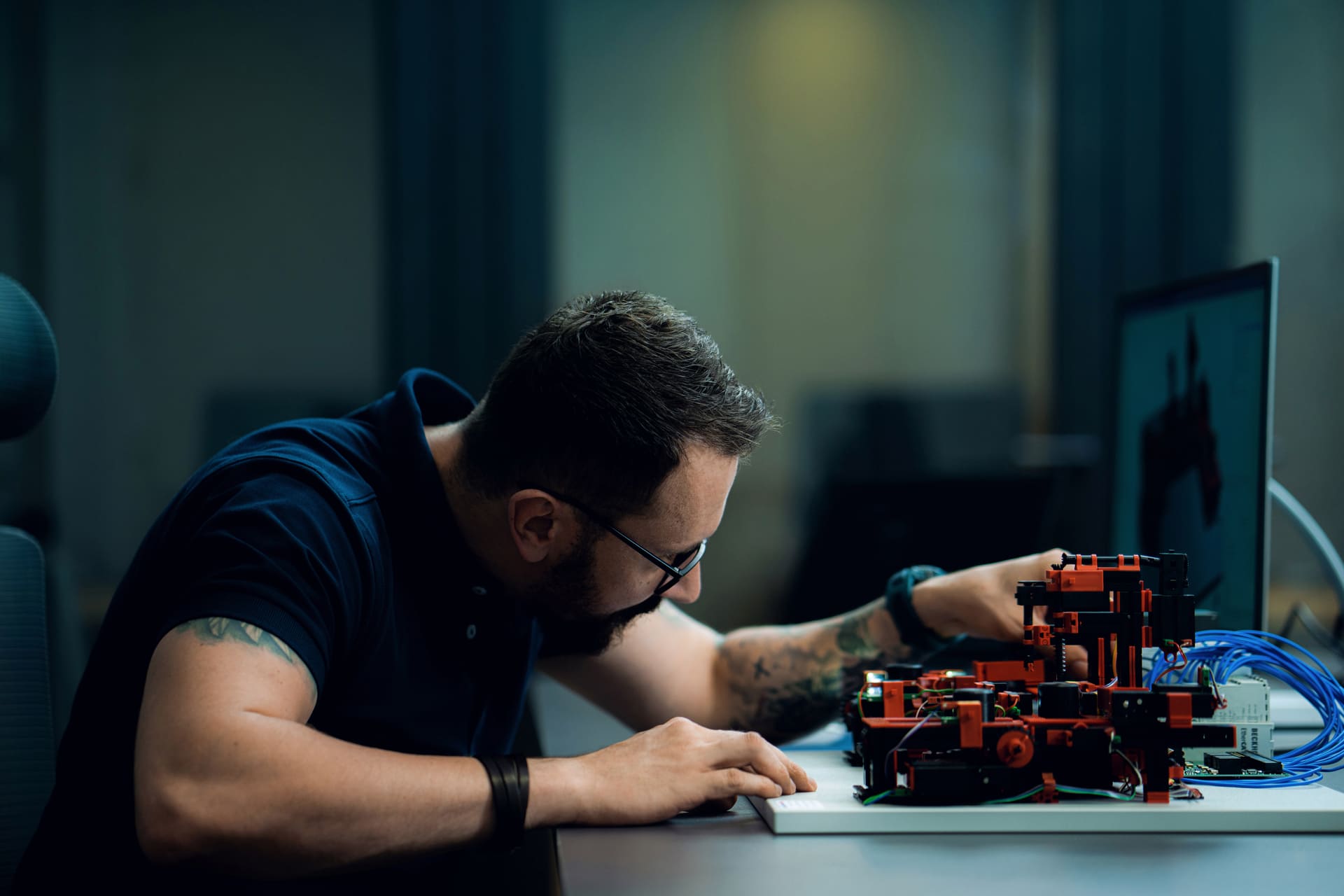

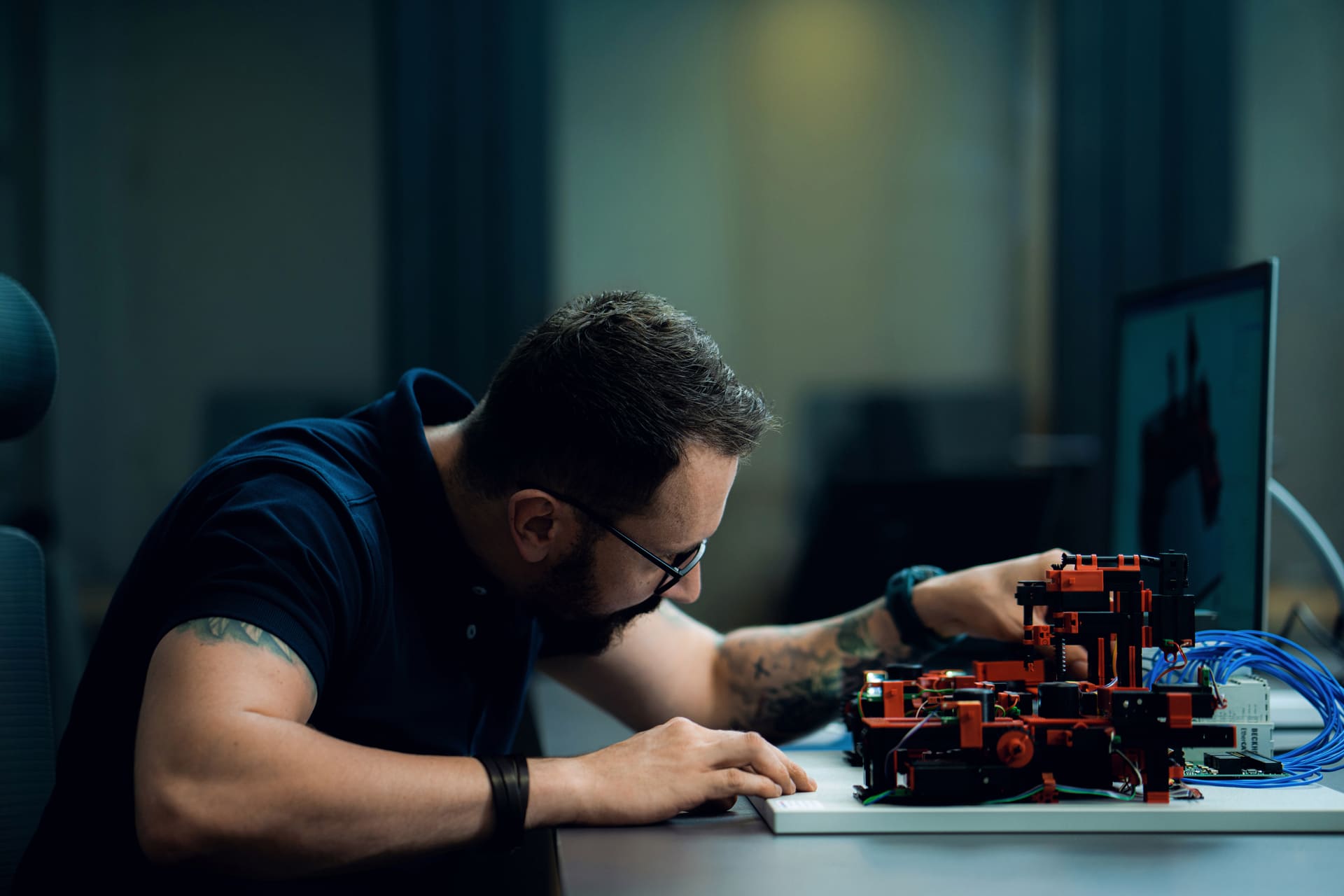

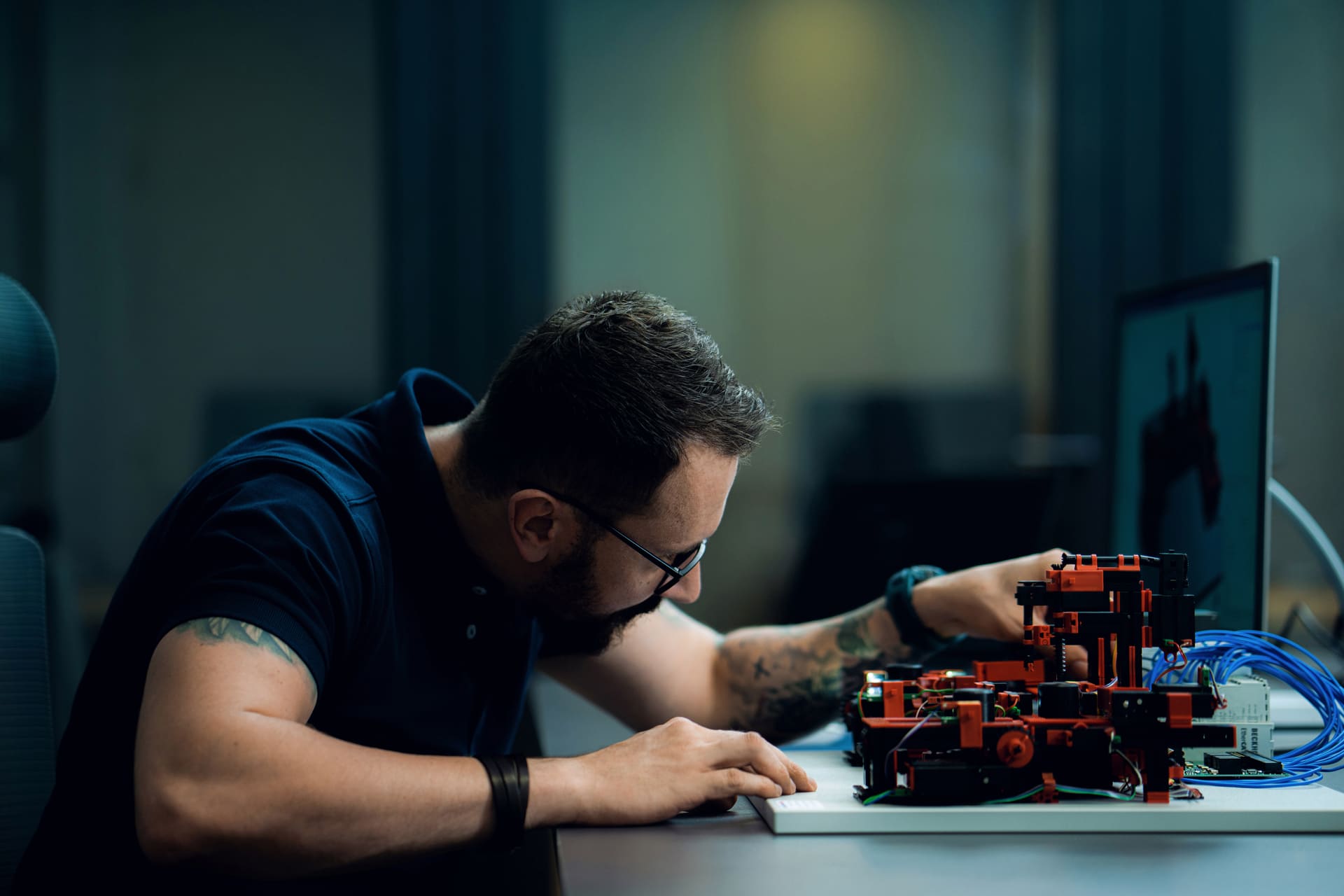

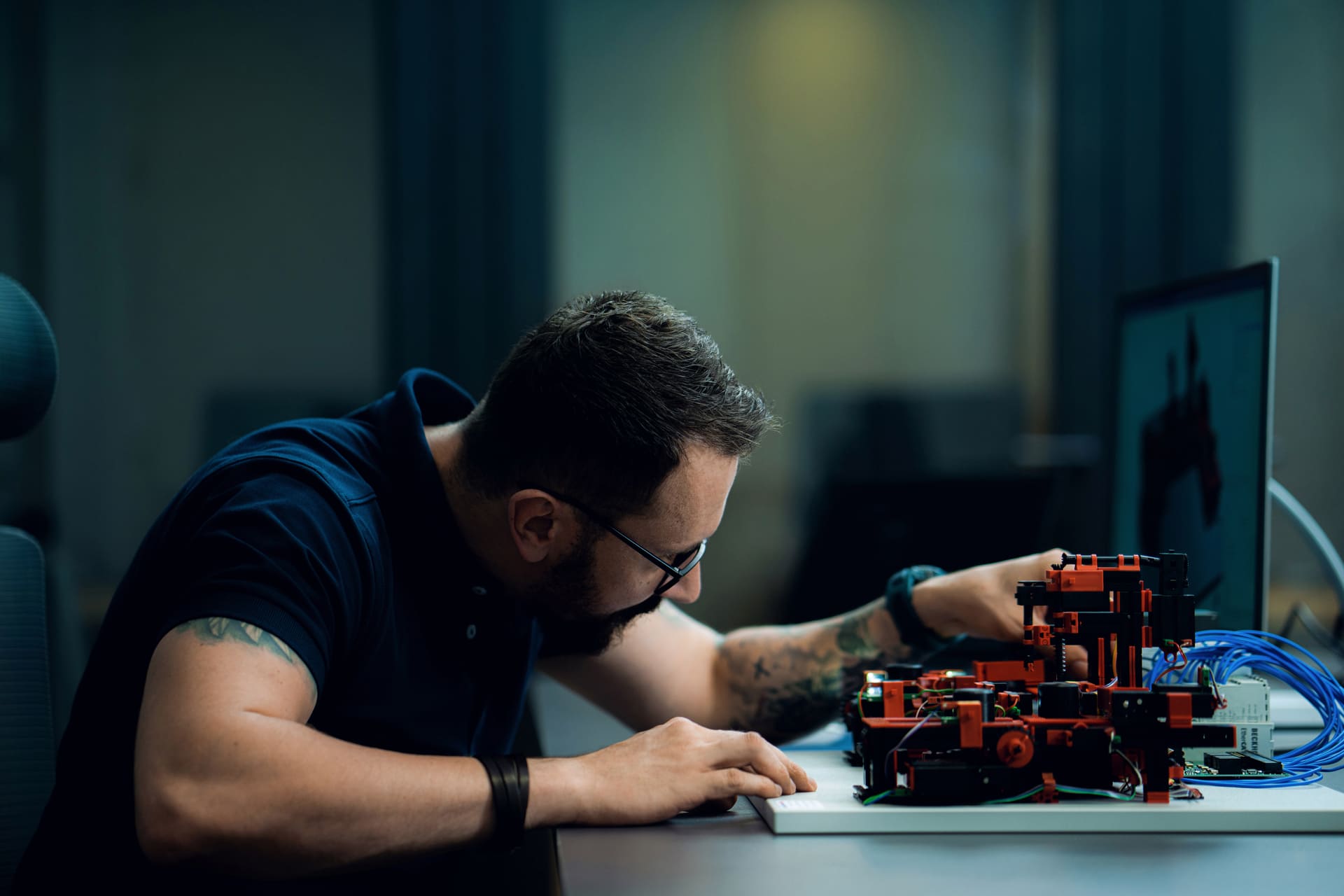

MAHLE commissioned Selmo to modernize an End-of-Line-Tester for the quality control of a production line. The goal was to maintain the existing machine and replace the complex and vulnerable control system. The process flow was optimized by commissioning the new control system and the cycle time improved.

Facts

MAHLE Hardware

- 2 axes (Parker, IAI)

- 2 cylinders (Festo)

- 1 gripper

- 1 jaw chuck

- 1 load cell

- 1 measuring probe (Heidenhain)

- 1 calibration weight

Selmo control concept

- PLC Beckhoff TwinCat

- 4 RS232 interfaces

- 4 TCP/IP Ethernet interface

- 1 bus system EtherCat

- 1 encoder

- 16 digital inputs

- 16 digital outputs

- 8 analog inputs 0-10V

- 4 analog inputs 4- 20mA

- 4 analog outputs 4- 20mA

Selmo Solution

- 1 Plant

- 1 Hardwarezone

- 2 Sequences

- 196 Zones

- 6 CMZ

- 192 Steps

- 249 Parameter

- 32 Assemblies

Selmo Steuerungskonzept

- PLC Beckhoff TwinCat

- 4 RS232 Schnittstellen

- 4 TCP/IP Ethernet Schnittstelle

- 1 Bussystem EtherCat

- 1 Encoder

- 16 Digitaleingänge

- 16 Digitalausgänge

- 8 Analogeingänge 0-10V

- 4 Analogeingänge 4- 20mA

- 4 Analogausgänge 4- 20mA

MAHLE Hardware

- 2 Achsen (Parker, IAI)

- 2 Zylinder (Festo)

- 1 Greifer

- 1 Backenfutter

- 1 Kraftmessdose

- 1 Messetaster (Heidenhain)

- 1 Kalibriergewicht

Selmo Solution

- 1 Plant

- 1 Hardwarezone

- 2 Sequenzen

- 196 Zonen

- 6 CMZ

- 90 SPS Ein- und Ausgänge

- 192 Schritte

- 249 Parameter

- 32 Assemblies

Implementation

The end-of-line-tester was an outdated system that urgently needed to be modernized. The system was programmed on a proprietary software environment with which only specific experts were familiar. The biggest challenge here was a required change in the software and communication of the sensor technology. This conversion could not be carried out because the people responsible were no longer available. Contracts with third parties failed.

Selmo rethought the process and automated the inspection station. The software environment was migrated to an open and standardized platform. The sensor technology was equipped with modern interfaces and integrated into the Selmo system.

Due to the successful commissioning of the end-of-line-tester, another testing station was modernized with Selmo.

"The programming sequence, which is otherwise difficult to keep track of, is easy to follow and understand, thanks to Selmo. This means that the machine's status can be understood even without a programmer and can be corrected in case of any errors."

Employee - MAHLE Filtersysteme Austria GmbH

Result

By working with Selmo, MAHLE was able to significantly improve the quality of the test station while simplifying the control of the system. Selmo is a software solution that automatically generates the PLC code for the machine and enables simple and transparent communication between all parties involved.

With Selmo, MAHLE was able to program and commission the test station in record time and avoid unexpected failures.

.png?width=1200&height=1200&name=orig_contact_005%20(1).png)