Become a coding professional in the shortest time

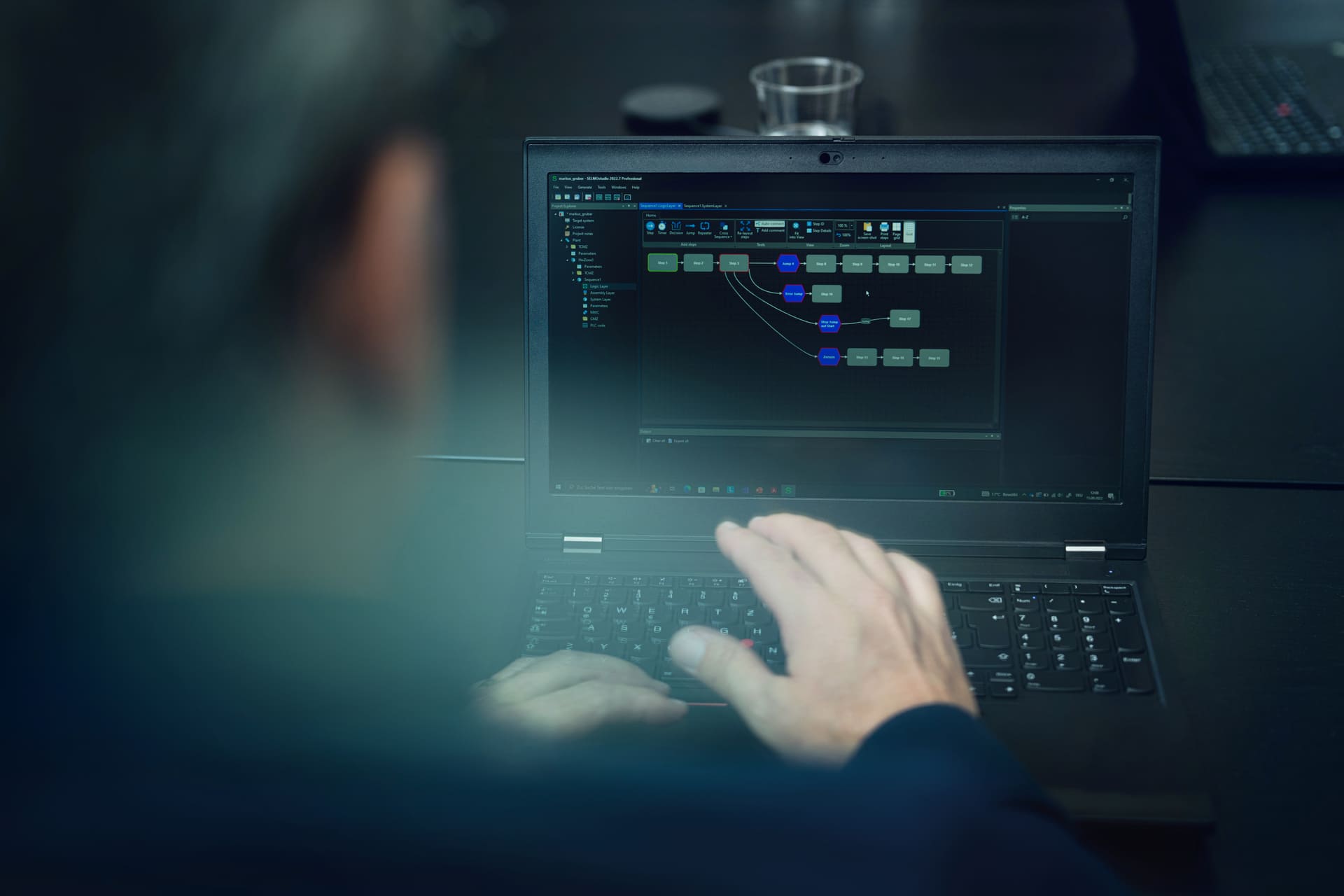

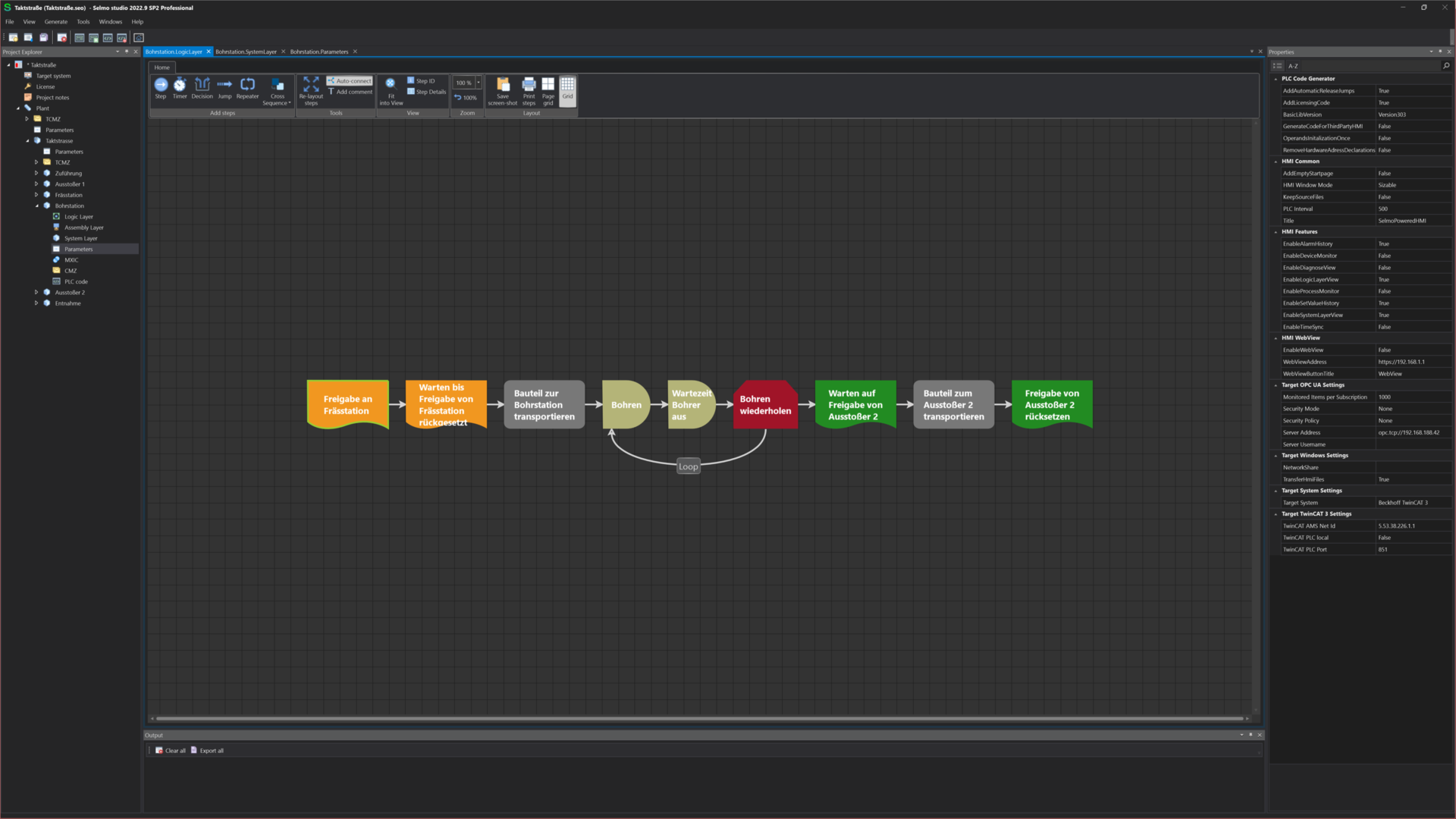

Selmo offers a standard that creates a universal-uniform structure in the program, ensures transparent communication between the machine user, mechanical engineer, and PLC programmer, and automatically implements the simple operating system of the machine. The Selmo Studio is the tool that converts the machine's process into a digital model. All the necessary functions for modeling the process, creating the software, importing, and implementing are available in Selmo Studio. The process model provides the target state, which is constantly compared with the actual state of the machine. All deviations are displayed in real time and with a "bit-by-bit" accuracy. In this way, Selmo not only controls but also monitors the device.

In two weeks, you can learn about all these features and functions with the Indexing line model in our Selmo Academy!

Become part of a unique and innovative technology and reach for new possibilities in digitalization!

Service:

Selmo Academy

Industry:

Automation technology

Location:

Global

Project overview

Project scope

-

20 PLC inputs and outputs

-

6 sequences mit 134 steps modeled in Selmo Studio

-

55 steps

-

71 zones

-

Over 3000 lines of Code

Project goals

-

Become a PLC programmer in record time.

-

Whether you're a newbie or an expert, anyone can use Selmo in no time.

-

As an experienced Selmo modeler complete this plant in 2 hours.

About the Selmo Academy

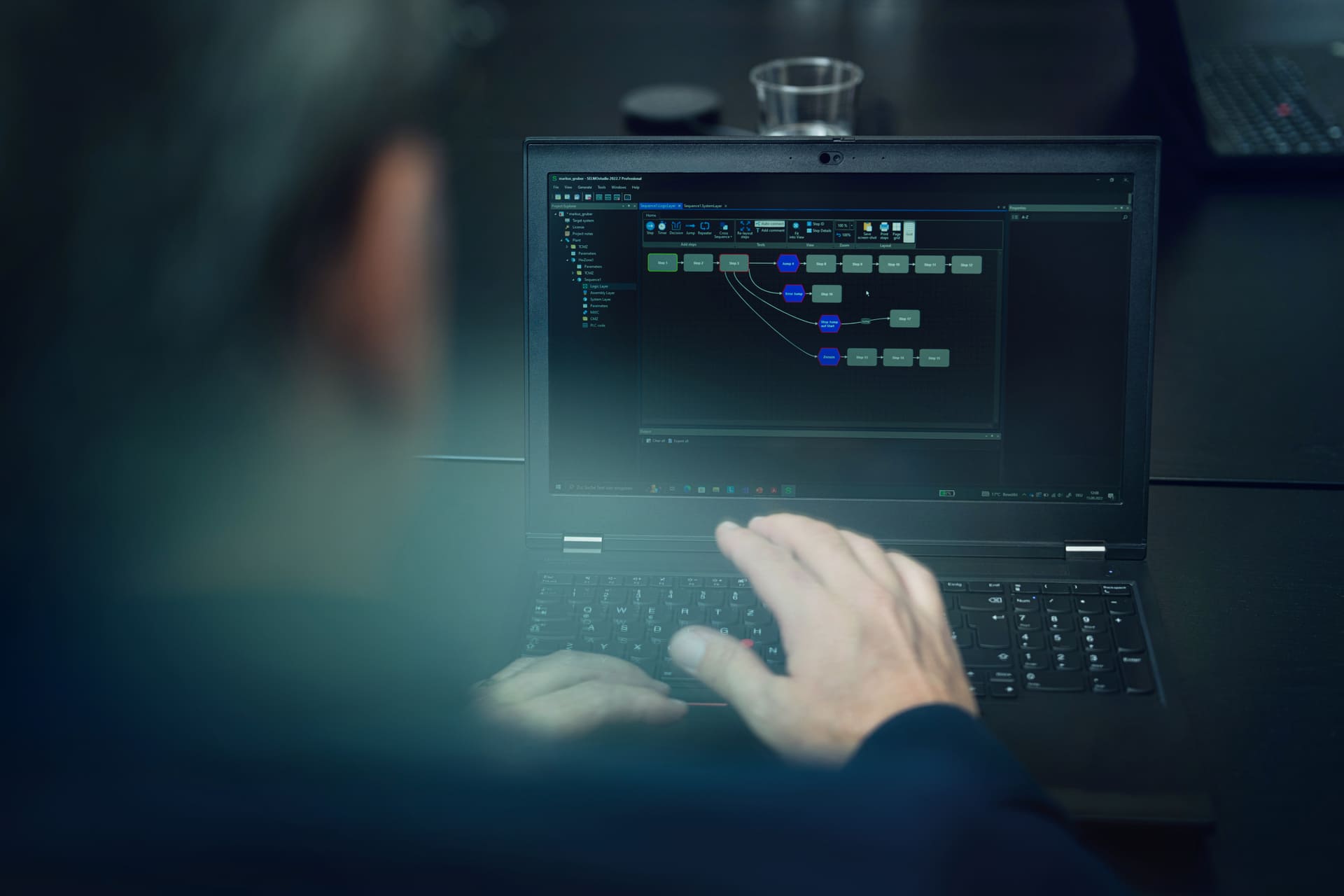

The Selmo Academy offers online and classroom courses to enable anyone to learn about the Selmo Solution easily and quickly. The Selmo training offers range from Kick off workshops for introduction, to classes for newcomers, to advanced training opportunities for experts.

The Selmo Academy explains in detail the new patented method of programming, and how to use the Selmo Studio and concludes with a practical application example of the Indexing line. Selmo is standardization at the highest level!

"I found the training on Selmo Studio essential and good for getting started. Through personal contact, questions and problems could be solved directly, which I would have only noticed later. Whether you are an experienced PLC programmer or a beginner, everyone can learn and master programming with Selmo."

Yanic-Claudio Ascari - HTL Saalfelden

"The Selmo software is an impressive tool. Particularly convincing is the time-saving and monitoring. It is easy to learn the software; the explanatory videos, and the Selmo Helpcenter were a great help. Mr. Herz supported me in case of questions or ambiguities."

Emil Miklautsch - HTL Wolfsberg

"The Selmo method is very impressive, and it saves much time. Furthermore, learning the Selmo method is not that difficult and very easy to understand."

Florian Jöbstl - HTL Wolfsberg

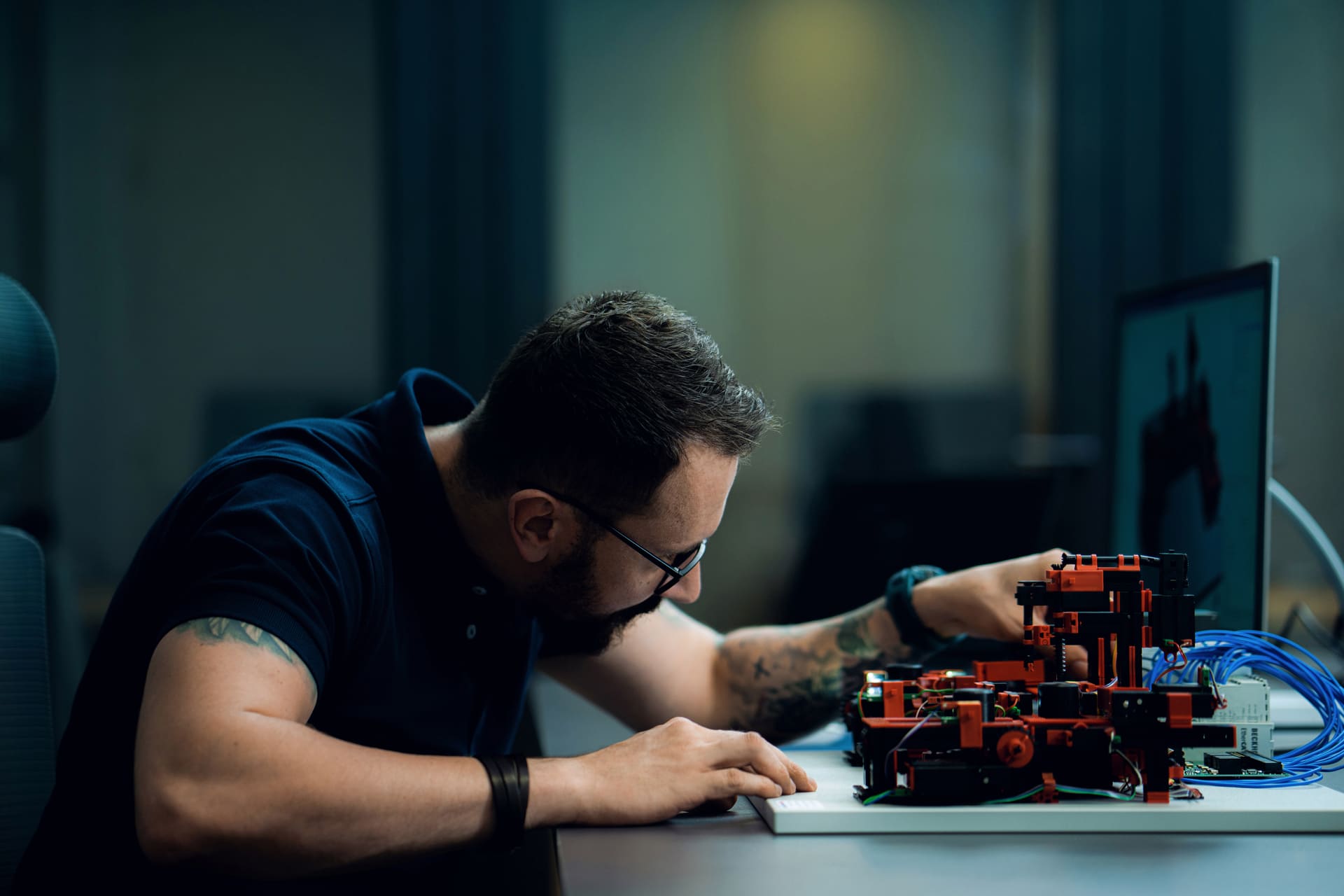

Indexed Line

The Fischertechnik Indexing line is a model of an actual production plant with conveyor lines. The processes are simulated as in the real industrial environment. The actuators and sensors are controlled and monitored via the installed PLC. The model aims to represent the logical sequence in a process model in Selmo Studio and to put the plant into operation.

The plant is logically divided into the following stations:

- Feeder

- Pusher 1

- Milling station

- Drilling station

- Pusher 2

- Removal