About EXARON GmbH

The mission of EXARON is to enhance the economic success and sustainability of companies in the secondary sector. This is achieved through the innovative combination of three-dimensional simulation solutions with industrial-grade immersive technologies.

EXARON envisions a world where Extended Reality (XR) in the industrial environment is not only accepted but becomes the standard. Their goal is to realistically and location-independently visualize, test, optimize, and learn complex processes and systems, without wasting resources or harming the environment.

Services:

New plant

Industry:

Machinery & plant manufacturing, Automation industry

Location:

Haselsdorf-Tobelbad, AUT

Project overview

Project scope

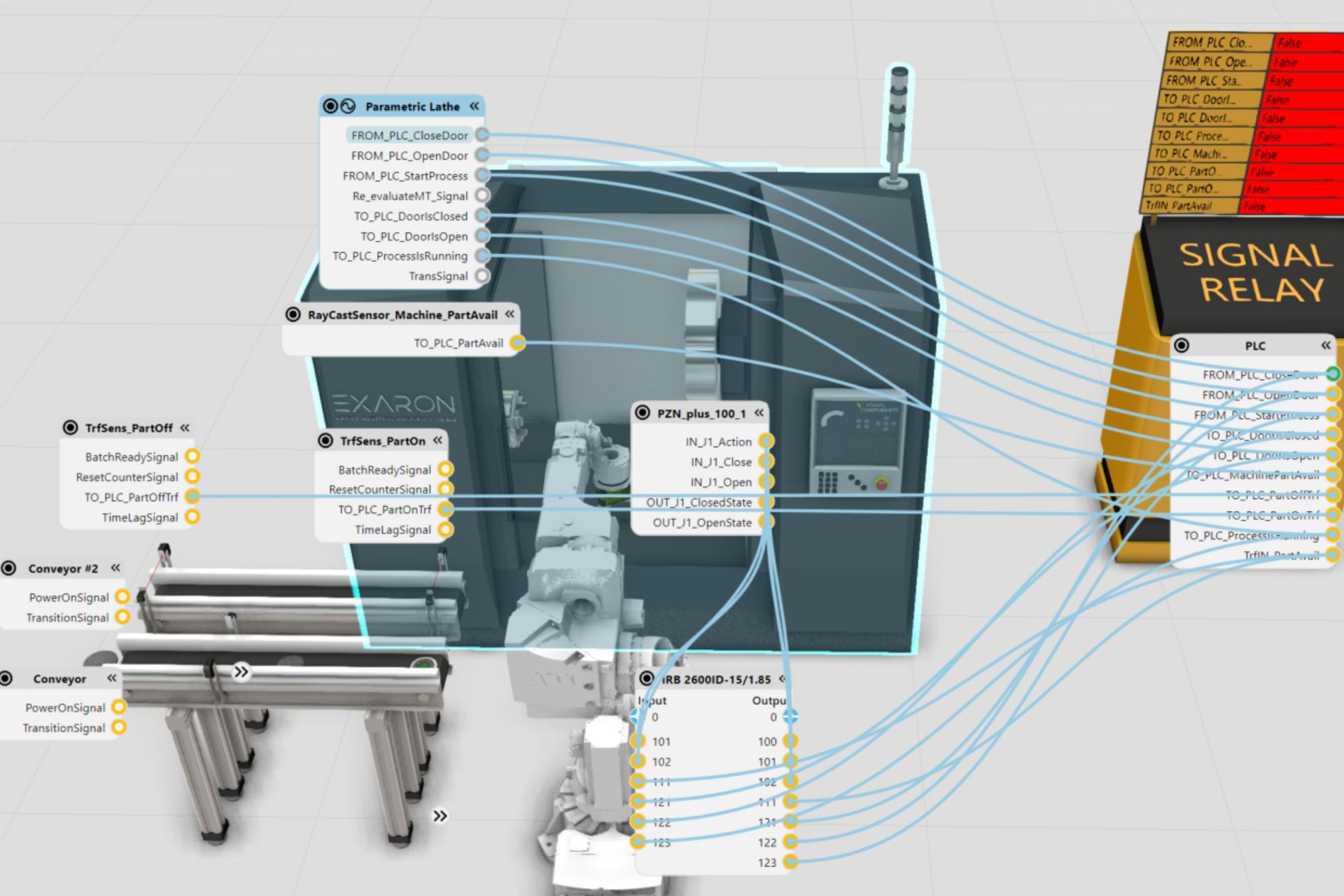

- Modeling effort: approximately 30 minutes

- 1 hardware zone

- 3 sequences

- 28 steps

- 32 zones

- 3 constantly monitored zones

- 2079 lines of code

- Headcount: 1 person

Project timeline

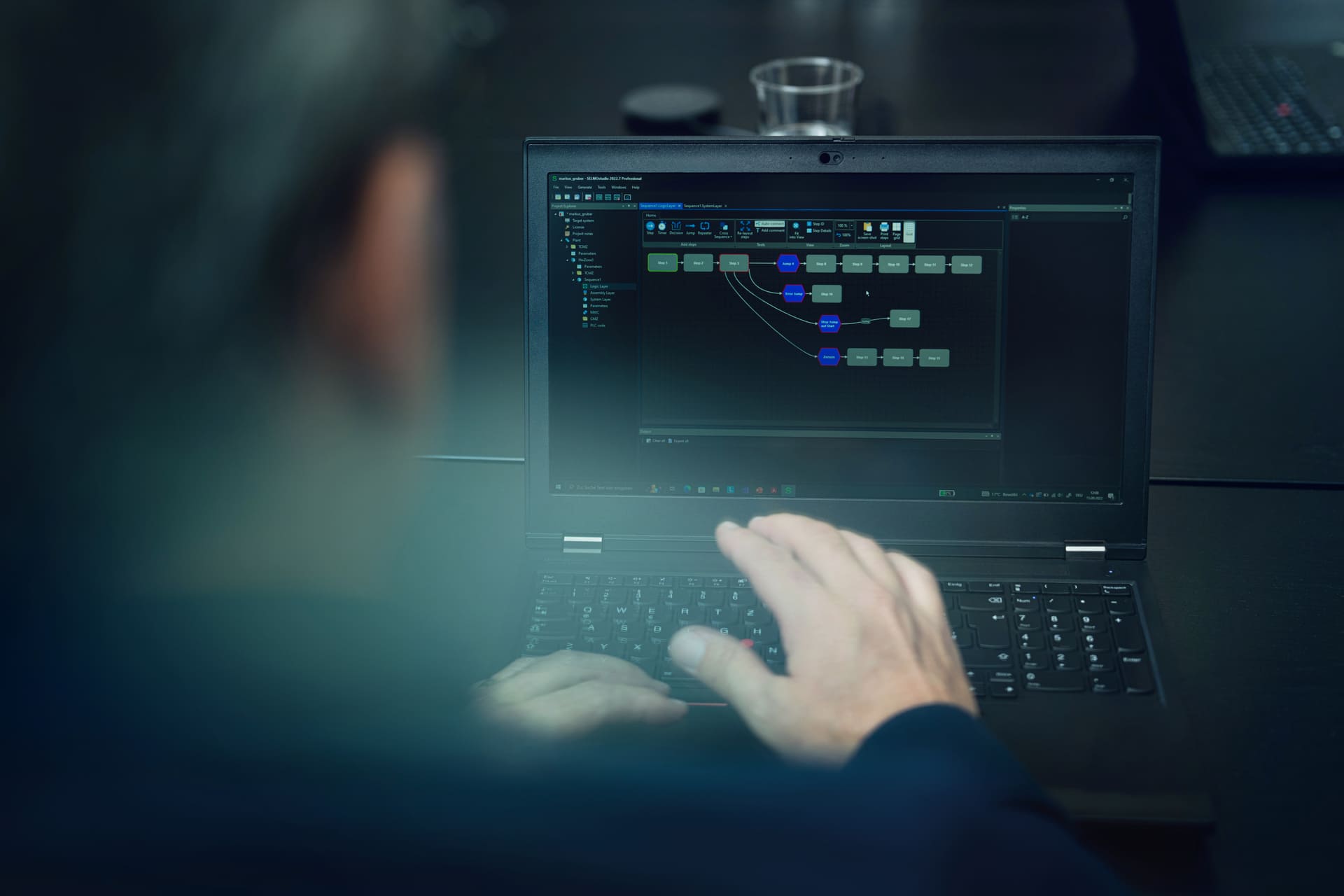

- The simulation was implemented in Visual Components by EXARON.

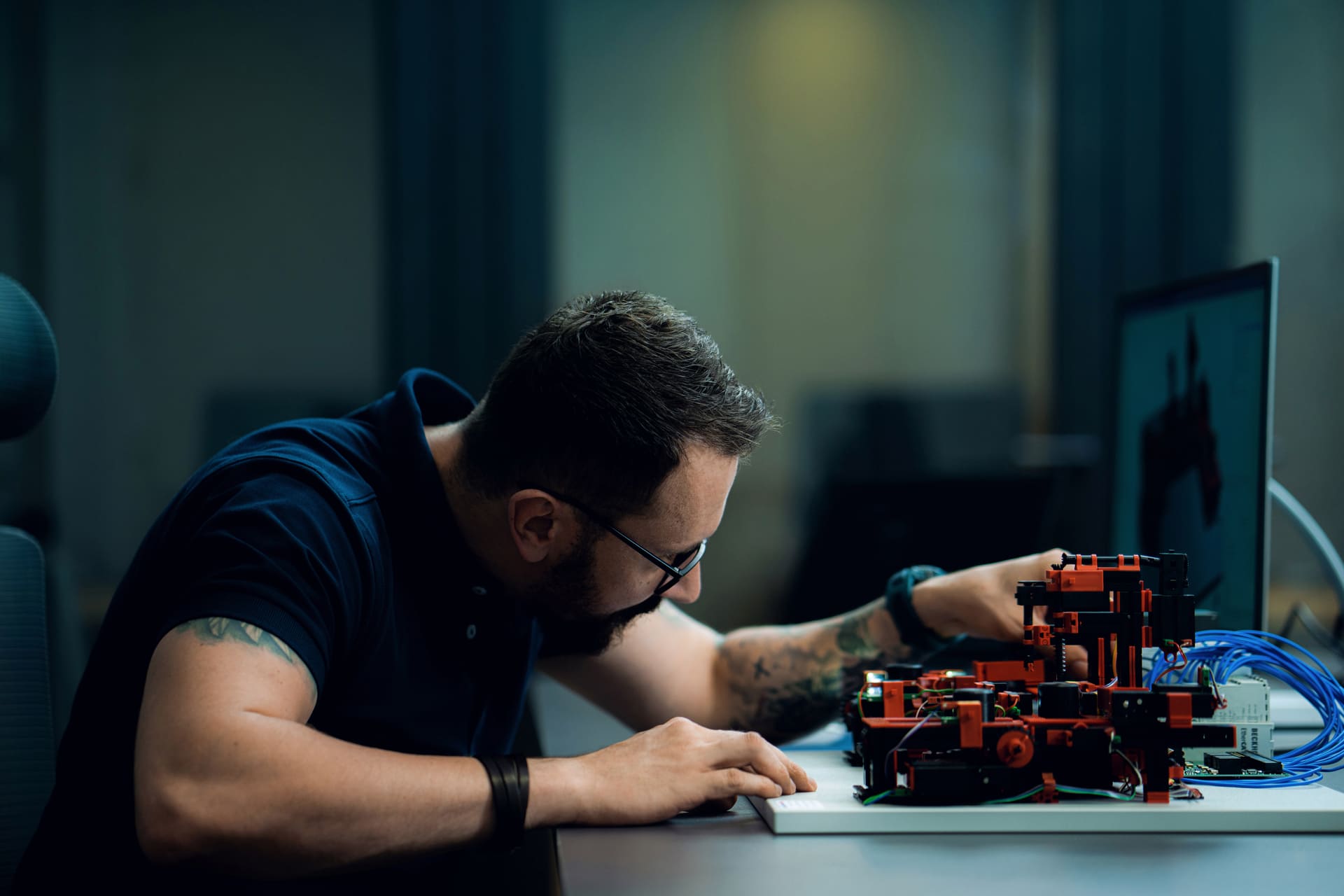

- Virtual commissioning took place in a workshop to integrate the simulation with the actual PLC.

- The task was to replace the scripts of the simulation with the real PLC program.

Initial situation & challenges

The challenge was that the results of the simulations could not be directly translated into the programming logic. Despite defining optimal processes, the complete PLC code was lacking in the end. Against this backdrop, the goal was to seamlessly integrate the insights gained from the simulations into the real programming, thereby automating the CNC machining station with the input and output conveyor system.

Implementation & result

The consistent application of Selmo's technology enables EXARON to immediately provide their customers with a basic logic or, in the best case, a complete programming code through simulations. This efficient and sustainable approach provides companies with the opportunity to relieve their own personnel and achieve a faster transition to the commissioning phase.